corporate video presentation

For more than 40 years we have been producing shoes designed to protect feet in the best way possible. We take care to make them safe not only from dangers due to possible accidents, but also from wear and tear that hard working inevitably exerts on our bodies.

GIOVANNI CILENTI – CHIEF EXECUTIVE OFFICER

Ethics & Quality

The ethical code adopted by panther represents the “charter of fundamental rights and duties” which clarifies the ethical and social responsibilities towards shareholders, employees, collaborators, suppliers, public bodies and customers.

Panther complies with the ethical principles of SEDEX® which is the largest platform in Europe for collecting and processing data on the ethical behaviour of supply chains and internal relations. Panther intends to enhance the people and organizations involved in its business through the values of respect and trust. Panther meets the highest European ISO 9001 certification standards; since 1998 has obtained the CSA certification for the Canadian market, ASTM for the U.S.A. and DGUV 112-191 for German market.

PROCESSES

Over time, Panther has updated its facilities and production processes, including energy supply management, plant insulation, and production equipment. In this context, the introduction of the DESMA injection machine allows, for specific applications, the controlled use of a defined proportion of PU production scrap in the manufacture of midsoles. Raw materials are sourced from suppliers compliant with current European regulations, including Regulation (EC) No. 1907/2006 (REACH)

Lean Thinking

The Lean thinking adopted in Panther aims to reduce waste to create excellent standardized processes at low cost through the active involvement of people. This system has been adapted to all sectors and all company areas. Research obsessive waste (MUDA) and empowerment of corporate resources to create added value, for continuous improvement. Starting from the analysis of the warehouses and intervening subsequently on production processes. The use of tools and was introduced evaluation indexes, and a clear training plan for all staff.

Production

Research, design, injection, and testing are carried out at the Bovolenta (PD) headquarters.

The DESMA 24-station injection machine allows, for specific applications, the controlled use of granulated PU derived from production scrap in the sole injection process.

At the two production sites of PANTHER ALBANIA sh.p.k. in Vlorë and Burrel, uppers are manufactured, with all production phases carried out under the supervision of specialized internal technical staff.

Suppliers

All companies that collaborate with Panther comply with current European regulations and the ethic code. Each production phase takes place under the supervision of Panther’s specialized technical representatives. Selected suppliers include Italian brands such as BASF, TEXON, WIND TEX, PREALPINA, EUROSUOLE, MONTECNO.

FINANCIAL HIGHLIGHTS

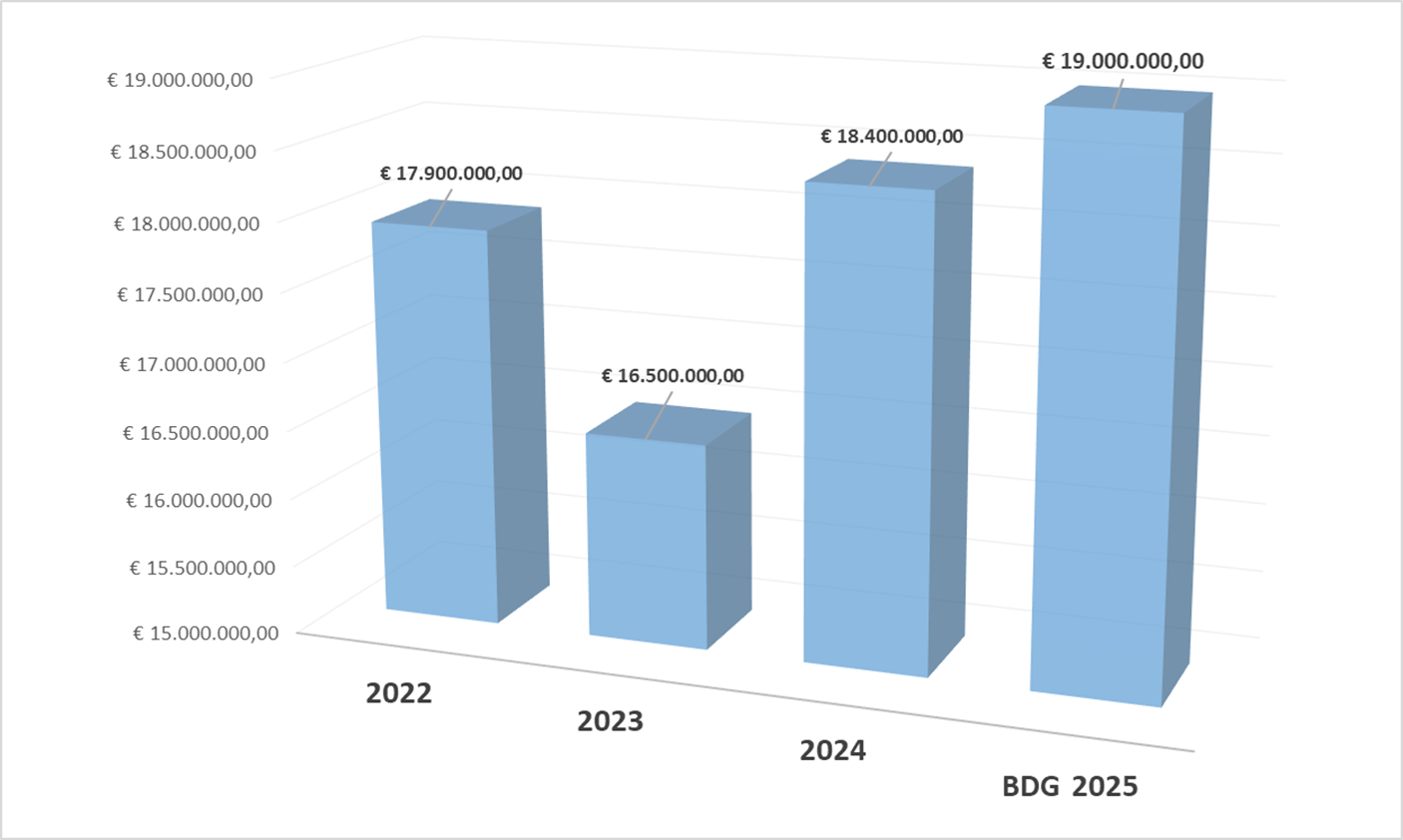

TURNOVER

SALES AND MARKET

DISTRIBUTION

IT ITALIA

BO BOLIVIA

CW CURACAO

CZ REP.CECA

SL SLOVAKIA

DE GERMANIA

DO DOMENICAN REPUBLIC

FI FINLAND

FR FRANCIA

GB GRAN BRETAGNA

AT AUSTRIA

CH SVIZZERA

ES SPAGNA

RO ROMANIA

NL OLANDA

PT PORTOGALLO

HU UNGHERIA

NZ NUOVA ZELANDA

PL POLONIA

CA CANADA

GH GHANA

IE IRLANDA

IN INDIA

NG NIGERIA

NO NORVEGIA

SG SINGAPORE

AE EMIRATI ARABI

BG BULGARIA

BH BAHREIN

CM CAMERUN

CN CINA

DK DANIMARKA

EE ESTONIA

GR GRECIA

HR CROAZIA

ID INDONESIA

IL ISRAELE

LT LITUANIA

MU MAURITIUS

MY MALESIA

NC NEW CALEDONIA

RS SERBIA

SI SLOVENIA

SK SLOVACCHIA

SM SAN MARINO

TN TUNISIA

TR TURKMENISTAN

SE SVEZIA

ZA SUD AFRICA

AU AUSTRALIA

OM OMANI

QA QATAR

SA ARABIA SAUDITA

TH TAILANDIA

AL ABANIA

KG KAZAKISTAN

PH FILIPPINE

BE BELGIO