How much does lightness weigh?

LET’S CLARIFY THE CLICHÈ

If you think that a safety shoe should be as light as possible, you are right. However, if you also think that it must be the lightest at all costs, then you are wrong.

The difference between the two previous statements is not a matter of subtlety. Choosing a safety shoe using absolute lightness as the exclusive criterion will most likely lead you to wear a shoe that, in a short time, will expose you to a series of risks and/or imbalances.

The lightness of the safety shoe is a relative concept. The “right” weight is given by the sum of all the best components and technologies needed to obtain the right balance of the shoe.

For example, the ANATOMIC SOLE, the anatomical shape of the injected midsole (unchangeable for the entire life of the shoe), slightly increases the weight in grams of a shoe, but above all increases the comfort of the foot while respecting its anatomy. Not only that: the anatomical shape enhances the beneficial properties and functionality of the custom-made insoles, as well as increasing their durability.

The injected PU/bi-density sole also increases the number of grams of a shoe but what increases most is the safety and comfort given by correct cushioning.

RIGT WEIGHT = RIGHT BALANCE

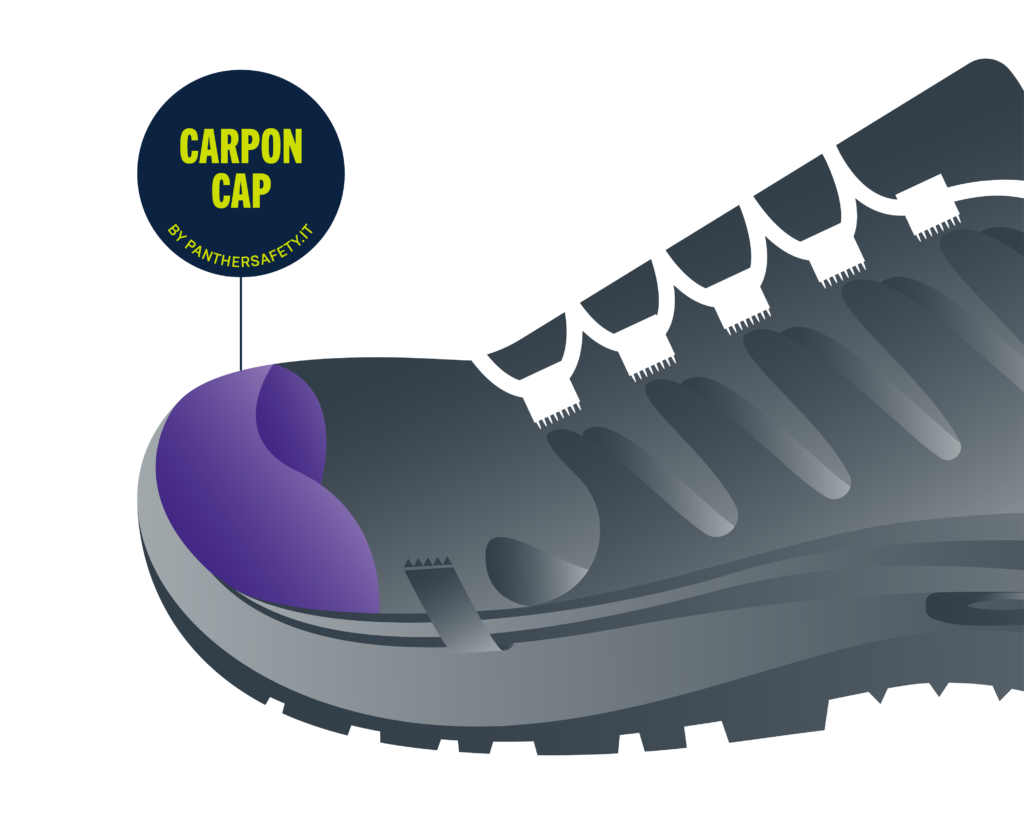

The CARBON CAP, an exclusive carbon fiber toe cap, is much lighter than the usual protective aluminum or steel toe caps but, with the same protection, it guarantees a wider fit, better thermal insulation, and greater comfort, as well as respecting fingers and toenails.

In short, lightness is not measured only with a scale but with the real benefits brought by wearing ABOUTBLU shoes.

THE RIGHT WEIGHT

In the case of footwear suitable for more extreme work environments such as those of the Heavy Duty and Oil&Gas families, the weight inevitably increases as they are mid footwear or boots which ensure all the safety and comfort characteristics.

QUANTITY OF COMPONENTS = QUALITY

To increase comfort, therefore, there is a need for the addition of essential components which can also increase the weight of the shoe, albeit by a few grams but, as we will explain below, giving up an essential component in exchange for greater lightness when putting on it creates many problems and consequently more marked and dangerous discomfort in a short time.

Aboutblu adds in the shoes it produces a quantity of components such as Carbon Cap, Composhank, Shield Tex, heel reinforcement and Silver Strip Discharge (SSD) essential to obtain an uncompromising level of benefits. To these must also be added the extreme technical complexity of the soles, uppers, linings, membranes and insoles, each designed to deal with different situations. It goes without saying that such a quantity of components, necessary to ensure performance, is reflected in the weight of the shoe.

QUANTITY OF COMPONENTS = QUALITY

There is a minimum threshold of quantity of material used in the construction of a safety shoe (as in the case of the polyurethane of the sole) below which it is best not to go to protect it from wear in a short time. Sacrificing a quantity of material with the sole purpose of further lightening the shoe would lead to rapid deterioration and compromise of the structural balance.

LAST AND BALANCE

The shape of the sole also influences the appearance of the weight. Aboutblu footwear is large, made using a greater quantity of material than standard practice.

This width allows the expansion of the foot tissues during work stress, allowing better blood circulation and optimal muscle performance. A shoe with a narrow fit tends to swell a foot under stress and risks compromising overall balanc

AVOID THE GONDOLA EFFECT*

*The góndola is the typical boat of Venice and has a very pronounced curved hull shape. Hence the invention of the expression ‘gondola effect’ to indicate a foot constricted in a shoe shape that does not allow the heel and toe to rest simultaneously and perfectly on the ground.

The weight of Aboutblu shoes is correctly balanced from the heel to the toe allowing the right roll. This prevents the shoe from resting completely on the ground, in which case the heel and toe remain raised, producing a gondola effect*: the greater the instability of the support, the greater the postural compensation.

The flexion of the toe, both when walking and when flexing the foot in positions on the ground, must instead allow a harmonious distribution of the lines of force, thus reducing the risk of possible stress fractures.